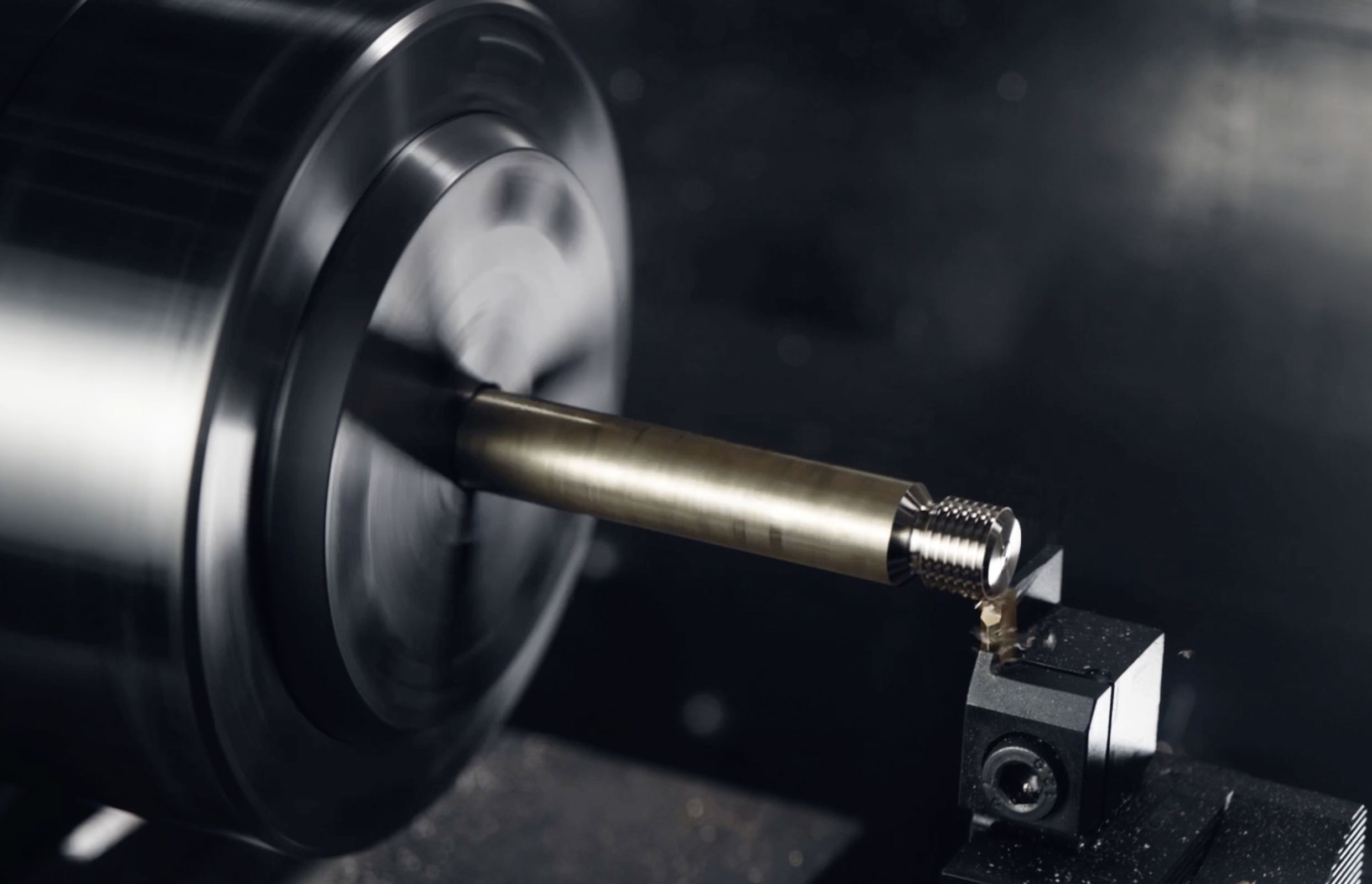

With its ecoline alloys, Wieland is a driving force when it comes to lead-free materials, recycling, and sustainability. Among other things, we ensure clean drinking water as well as pollutant-free products. Wieland ecoline is the answer you’re looking for to safeguard your future business success – providing unprecedented levels of machinability, formability, efficiency, and economy. Yet our lead-free machining materials alone aren’t sufficient to give you that decisive edge. It’s the expertise and personal commitment of our ecoline experts. We offer you comprehensive advice as you prepare to transition to lead-free alloys. And we remain at your side until everything is up and running – and beyond.

In short, let’s go lead-free!

Substitute your present lead-containing alloy with the lead-free ecoline® equivalent. Simply enter the product name in the field below.

| ecoline® | Wieland alternative | EN alternative | UNS alternative | Note |

|---|---|---|---|---|

| eco GS1® | GD1 | CC499K | ||

| eco KS2® | KC1 | CW113C | C18700 | |

| eco KS4® | K41 | C19150; C19160 | ||

| eco BS4® | B44 | CW456K | C54400 | |

| eco M58® | Even lower lead content than eco SZ4® | |||

| eco N59® | N48 | CW407J | ||

| eco SD4® | S40 | CW713R | C67420 | |

| eco SW1® | Z45 | CW602N | C35330 | Higher strengths compared to eco SW4® |

| eco SW3® | GD1 | CC499K | ||

| eco SW5® | Even lower lead content than eco SW1® | |||

| eco SX1® | S40 | CW713R | C67420 | |

| eco SZ3® | Z33 | CW614N | C38500 | |

| eco SZ4® | Z41 | CW617N | C38500 | |

| eco SZ5® | Z29 | CW612N | C37700 | |

| ecobrass SW4® | Z45 | CW602N | C35330 | |

| eco SZ2® | Z33; Z41 | CW614N; CW617N | C38500 |

Use our Product Finder to find the right ecoline® alloy for your application.

Erfahren Sie, wie Sie mit unseren bleifreien Legierungen die Qualität unseres wichtigsten Lebensfairs auch unter strengeren Werkstoff-anforderungen sicherstellen.

Starke mechanische Belastung, hohe Temperaturen Werkstoffe für Automobilanwendungen müssen was aushalten. Unsere ecoline Legierungen zeichnen sich durch Eigenschaften wie hohe Festigkeit und Verschleißbeständigkeit aus.

Elektrische Leitfähigkeit und hohe mechanische Festigkeit sind in der Elektrotechnik entscheidende Faktoren. Wir finden mit Ihnen den passenden Kupferwerkstoff für Ihre elektrotechnische Anwendung.

Dank unserer bleifreien ecoline Legierungen sind Produkte wie Uhren, Schmuck, Brillen oder Blasinstrumente gesundheitlich unbedenklich und geben Ihren Kunden ein gutes Gefühl.

There’s lead-free and there’s lead-free. After all, one alloy that’s designed to fit all can’t possibly meet your highly individual requirements. That’s why we at Wieland have come up with a range of lead-free products – products that are just right for applications in specific industries or at specific customers. Together, we’ll check out which ecoline alloy is the perfect fit for your particular needs.

Lorem ipsum dolor sit, amet consectetur adipisicing elit. Magni, explicabo?

Lorem ipsum dolor sit, amet consectetur adipisicing elit. Magni, explicabo?

Lorem ipsum dolor sit, amet consectetur adipisicing elit. Magni, explicabo?

Lorem ipsum dolor sit, amet consectetur adipisicing elit. Magni, explicabo?

Lorem ipsum dolor sit, amet consectetur adipisicing elit. Magni, explicabo?

Lorem ipsum dolor sit, amet consectetur adipisicing elit. Magni, explicabo?

Lorem ipsum dolor sit, amet consectetur adipisicing elit. Magni, explicabo?

Lorem ipsum dolor sit, amet consectetur adipisicing elit. Magni, explicabo?

Lorem ipsum dolor sit, amet consectetur adipisicing elit. Magni, explicabo?

Lorem ipsum dolor sit, amet consectetur adipisicing elit. Magni, explicabo?

Lorem ipsum dolor sit, amet consectetur adipisicing elit. Magni, explicabo?

Lorem ipsum dolor sit, amet consectetur adipisicing elit. Magni, explicabo?

Lorem ipsum dolor sit, amet consectetur adipisicing elit. Magni, explicabo?

Lorem ipsum dolor sit, amet consectetur adipisicing elit. Magni, explicabo?

Lorem ipsum dolor sit, amet consectetur adipisicing elit. Magni, explicabo?

Lorem ipsum dolor sit, amet consectetur adipisicing elit. Magni, explicabo?

Lorem ipsum dolor sit, amet consectetur adipisicing elit. Magni, explicabo?

Lorem ipsum dolor sit, amet consectetur adipisicing elit. Magni, explicabo?

Lorem ipsum dolor sit, amet consectetur adipisicing elit. Magni, explicabo?

Lorem ipsum dolor sit, amet consectetur adipisicing elit. Magni, explicabo?

Insight into our lead-free machining materials using the example of eco SZ3®

With our expertfinder, you will find the right ecoline expert for your application.

Talk to our experts about how to make the switch to lead-free ecoline alloys. Simply fill out the contact form or contact one of our experts directly.

We will be in contact shortly.

There was an issue. Please try again later. Thank you!